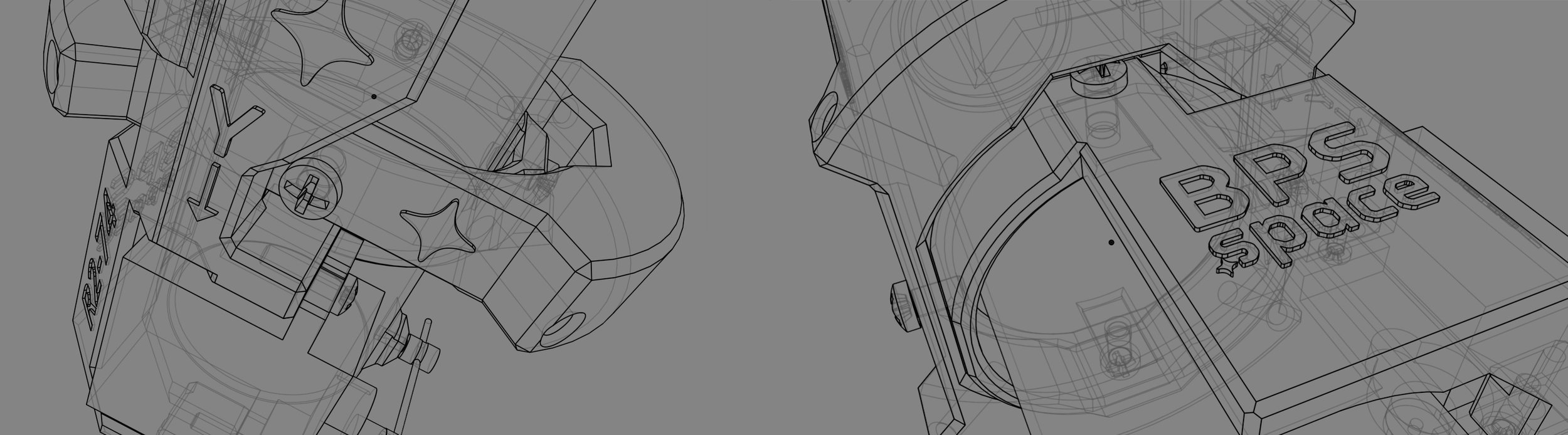

Thrust Vector Control

Developed over 3 years of iterative design with over 40 successful flights, this thrust vector control(TVC) hardware is used in nearly every BPS.space model rocket.

Overview

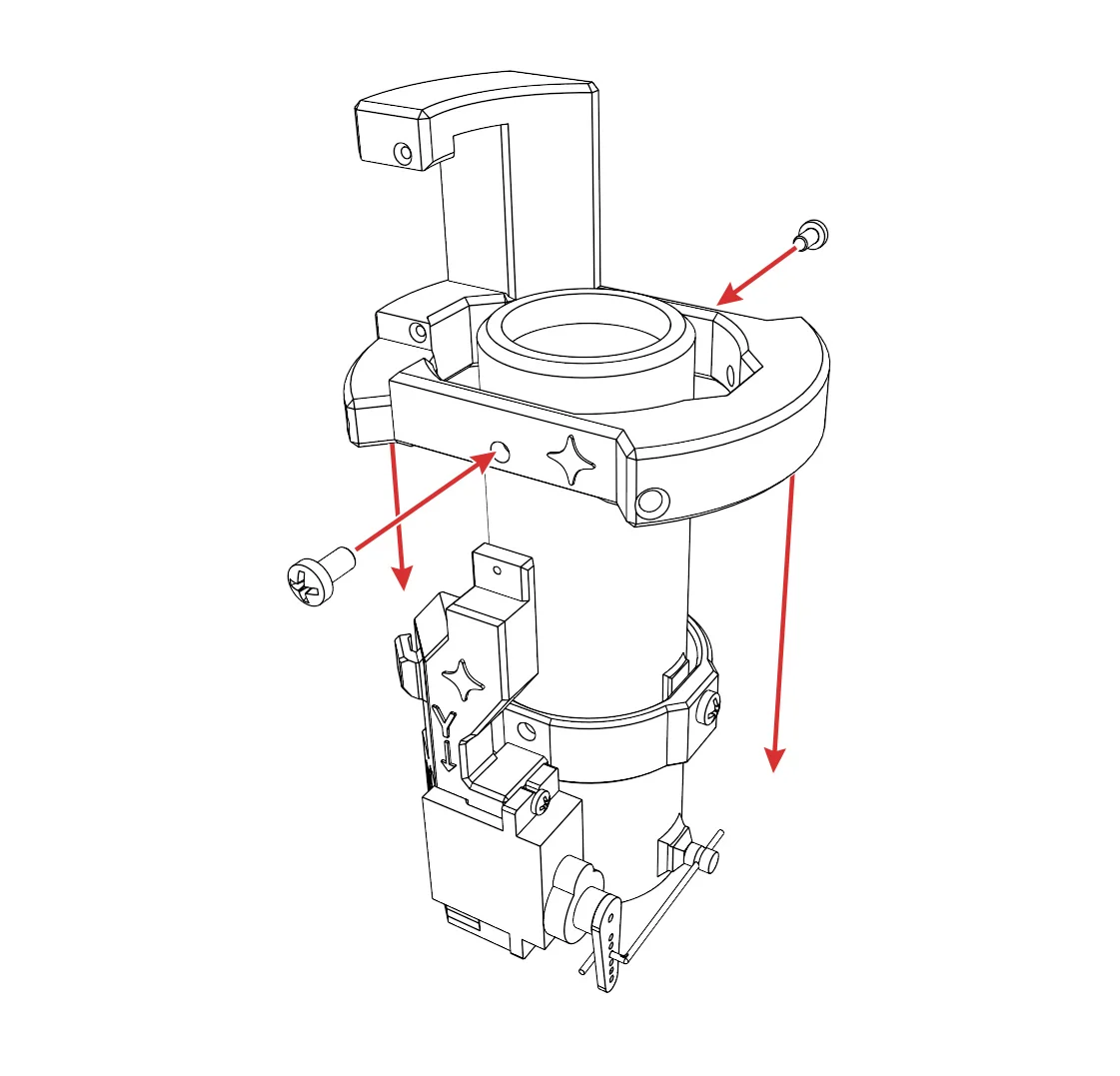

The major parts of the motor mount are 3D printed using PLA, which stands for polylactic acid. The structure and mechanics are built for 74mm thin-wall airframes and can withstand up to 40 Newtons of force, though it functions best with 5-20 Newtons of constant force. The mount can actuate ±5° with a full range max bandwidth of 13Hz, and nominal bandwidth of 25Hz. These parts were designed around low-cost and widely available components. Keeping repair costs low helps minimize the resources it takes to rebuild after any rapid unscheduled disassemblies.

Recommended Rocket Motors

Estes F15 or E9*

Apogee F10 or E6*

Aerotech G8 or G11

The ideal motors for this TVC mount have a long burn time, an average thrust of 5-20 Newtons, and a flat thrust curve. This means the force produced over time should remain fairly constant. The motor sleeve can fit rocket motors with a diameter of up to 29mm.

*These motors may require the removal of the built-in ejection charge

A few quick notes!

You’re welcome to add thrust vector control to your own model rockets, but nearly all of the complexity involved is in the flight software, which is not publicly available yet. To build your own model rocket flight computer and software, check out the Landing Model Rockets video series.

These files come with cut and drill guides and a full set of instructions for assembly. If you’re just getting started with TVC, your first few tests will probably fail - it’s just very difficult to get right. That said, these designs will help you get a head start with development.